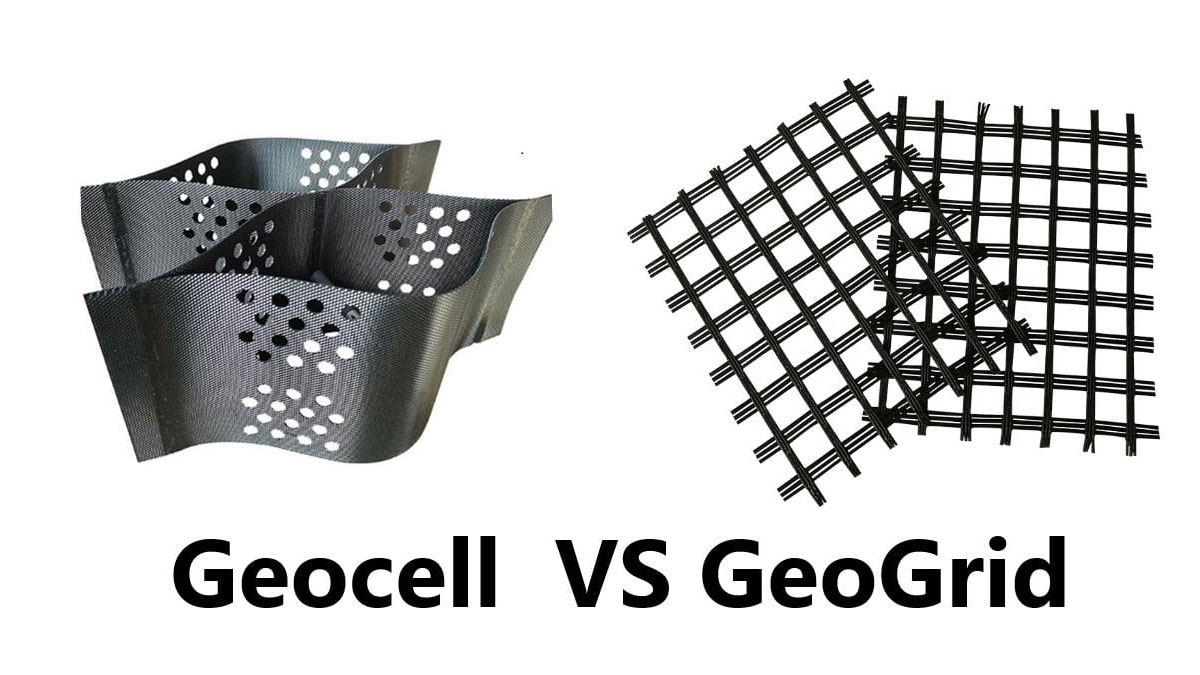

Geogrids and geocells are geosynthetic materials used for soil reinforcement. Geogrids are grid-like structures that provide tensile strength, while geocells are three-dimensional structures that confine fill material. Geogrids distribute loads and prevent soil deformation, while geocells enhance load distribution and prevent lateral spreading. In this article we discuss about difference between geogrid and geocell.

What are geocells?

Geocells are three-dimensional cellular confinement systems made from high-density polyethylene (HDPE) or other durable materials. They consist of interconnected, honeycomb-like cells that are filled with soil, aggregate, or other fill materials. Geocells are commonly used in civil engineering and geotechnical applications to provide stabilization, erosion control, and reinforcement.

When deployed, geocells form a rigid structure that confines and supports the fill material, creating a stable and load-bearing platform. The interconnected cells prevent lateral movement and help distribute loads evenly. Geocells can be used in various applications, including slope stabilization, retaining walls, road and railway construction process, channel protection, and land reclamation.

What are geogrids?

Geogrids are geosynthetic products made from polymers such as polypropylene or polyester. They are composed of a grid-like structure with open spaces between the intersecting ribs or strands. Geogrids are used in civil engineering and geotechnical applications to enhance soil reinforcement, provide stabilization, and improve load-bearing capacity.

The primary function of geogrids is to distribute and transmit loads over a wider area, thereby improving the structural integrity of the soil. They are commonly used in applications such as road and railway construction, retaining walls, embankments, and reinforced slopes.

Read more: Geogrid Retaining Wall Installation

The difference between geogrid and geocell in price

The price difference between geogrids and geocells can vary depending on several factors, including the specific product, manufacturer, location, and quantity required. However, in general, geocells tend to be more expensive than geogrids.

Geocells are typically constructed from high-density polyethylene (HDPE) or other durable materials, and their manufacturing process involves intricate cell structures. These factors contribute to higher production costs, which are reflected in the final price of geocell products.

On the other hand, geogrids are usually made from polymers such as polypropylene or polyester and have a simpler grid-like structure. Their manufacturing process is relatively less complex, resulting in lower production costs compared to geocells.

It’s important to note that the price difference can also depend on the specific application and requirements of the project. Certain geotechnical projects may demand the use of geocells due to their unique confinement capabilities, while others may find geogrids to be a more cost-effective solution.

To accurately determine the price difference between geogrids and geocells for a specific project, it is advisable to consult with suppliers, manufacturers, or local distributors. They can provide detailed pricing information based on the project specifications, quantities, and market conditions.

The difference between geogrid and geocell in installation

The installation of geogrids and geocells differs in terms of the process and techniques involved. Here are the key differences in installation between geogrids and geocells:

Geogrid Installation:

- Preparation: The soil surface needs to be properly prepared by removing any vegetation, debris, or loose soil. The subgrade may require compaction to achieve a stable foundation.

- Unrolling: Geogrids are typically supplied in rolls. They are unrolled and laid out on the prepared soil surface, ensuring proper alignment and overlap as per design specifications.

- Connection: Geogrid panels are connected at their overlapping sections using methods such as sewing, stapling, or heat bonding. This ensures a continuous reinforcement layer.

- Anchoring: Geogrids are anchored to the soil through methods like soil nails, spikes, or trenching. Anchoring helps to prevent movement or displacement of the geogrid during construction or subsequent loading.

- Placement of Overlying Materials: Once the geogrid is installed and anchored, additional construction layers such as aggregate, fill material, or pavement can be placed directly on top of the geogrid to complete the construction process.

Geocell Installation:

- Preparation: Similar to geogrids, the soil surface needs to be cleared of vegetation, debris, and loose soil. The subgrade may require compaction for stability.

- Unfolding and Placement: Geocells are supplied in a collapsed or folded form. They are unfolded and placed on the prepared soil surface, forming a three-dimensional cellular structure.

- Connection: Geocell sections are connected at the edges using interlocking mechanisms or fasteners provided by the manufacturer. This ensures a continuous and stable structure.

- Filling: The cells of the geocell are filled with soil, aggregate, or other suitable fill materials, creating a stable and reinforced structure. The fill material is typically compacted within the cells to achieve the desired compaction and load-bearing capacity.

- Placement of Overlying Materials: Similar to geogrids, additional construction layers can be placed directly on top of the geocell structure, such as aggregate or pavement, to complete the construction process.

The difference between geogrid and geocell in infill materials

The choice of infill materials for geogrids and geocells can vary depending on the specific project requirements and design considerations. Here are the key differences in infill materials for geogrids and geocells:

Geogrid Infill Materials:

- Granular Fill: Geogrids are commonly filled with granular materials such as crushed stone, gravel, or sand. These materials are compacted within the open spaces of the geogrid structure to provide stability and improve load distribution.

- Soil Fill: Geogrids can also be filled with soil, especially when the project aims to enhance soil reinforcement or provide a stable foundation for vegetation growth. The soil fill can include native soil or engineered soil blends based on the project requirements and soil characteristics.

- Aggregate Fill: In some cases, geogrids may be filled with aggregate materials, such as crushed stone or recycled concrete, to create a stable and load-bearing layer. This is commonly used in applications like road construction or load support platforms.

Geocell Infill Materials:

- Granular Fill: Geocells are designed to be filled with granular materials such as sand, gravel, or crushed stone. These materials provide stability, load-bearing capacity, and confinement within the geocell structure.

- Soil Fill: Geocells can be filled with soil, allowing for vegetation growth and erosion control. The soil fill provides a stable environment for plant roots and helps establish vegetation on slopes, embankments, or other green infrastructure projects.

- Lightweight Fill: Geocells can also be filled with lightweight materials such as expanded polystyrene (EPS) beads or lightweight aggregate. This type of fill reduces the overall weight of the structure while providing stability and load-bearing capacity.

The difference between geogrid and geocell in strength

Geogrids and geocells have different mechanisms of providing strength and reinforcement in geotechnical applications. Here are the key differences in strength between geogrids and geocells:

Geogrid Strength:

- Tensile Strength: Geogrids are primarily designed to provide tensile strength in both the longitudinal and transverse directions. The ribs or strands of the geogrid are engineered to resist tensile forces and distribute loads over a wider area. The tensile strength of geogrids allows them to withstand high loads and provide reinforcement to the soil or aggregate they are embedded in.

- Flexural Rigidity: Geogrids possess flexural rigidity due to their grid-like structure. This rigidity helps distribute loads and prevent differential settlement or deformation. Geogrids can resist lateral movement and provide stability to the soil or fill material, enhancing the overall strength of the structure.

Geocell Strength:

- Confinement Effect: Geocells derive their strength from the confinement effect they provide to the fill material within their cellular structure. The interconnected cells of the geocell system confine and stabilize the fill material, preventing lateral spreading and enhancing load-bearing capacity.

- Cell Wall Thickness: The thickness of the geocell cell walls contributes to its strength. Thicker cell walls provide increased stiffness and resistance to deformation, thereby improving the overall strength and stability of the geocell structure.

- Load Distribution: Geocells distribute loads over a larger area and reduce the stress concentrations on the soil or fill material. This load distribution mechanism helps improve the load-bearing capacity and overall strength of the geotechnical structure.

Conclusion

In conclusion, geogrids and geocells are both effective geosynthetic solutions for soil reinforcement. Geogrids offer tensile strength and load distribution, while geocells provide confinement and load distribution. The selection between the two depends on specific project requirements and soil conditions.