Geocells are innovative structures that have revolutionized soil stabilization and erosion control in civil engineering. In this article, we want to check what is geocell and talk fully about this practical product.

What are geocells and what are they made of?

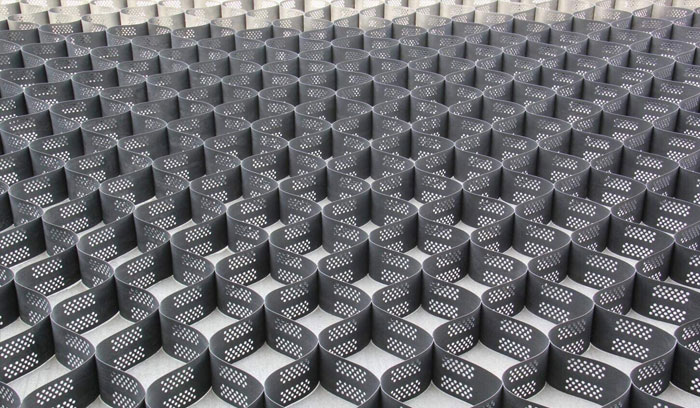

Geocells are three-dimensional, honeycomb-like structures made of a variety of materials, including high-density polyethylene (HDPE), polyester, and polypropylene. They are used in civil engineering and soil stabilization applications to reinforce soil and retain aggregates.

The HDPE are the most commonly used type and are made of high-density polyethylene sheets that are welded together to form a honeycomb-like structure. The cells are then filled with soil, aggregate, or other materials to create a stable foundation for roads, embankments, and other structures.

Geocells made from polyester and polypropylene are less common but are used in applications where chemical resistance or high-temperature tolerance is required.

The use of them can result in cost savings, reduced construction time, and improved durability of the structures they support. They are also environmentally friendly, as they can be easily recycled at the end of their useful life.

The history of geocells

The use of geocell in civil engineering and soil stabilization applications dates back to the 1970s. The first geocell product was developed in the United States by a company called Presto Products, which introduced the Geoweb geocell in 1982.

Initially, they were primarily used in military applications, such as building temporary roads and runways in remote locations. However, their use quickly expanded to other industries, including transportation, mining, and construction.

Over time, geocell technology has evolved to include different materials and designs. The earliest geocells were made of polyethylene, but other materials, such as polyester and polypropylene, have since been developed. In addition, the shape and size of them have been optimized to improve their strength and stability.

Today, geocells are used in a wide range of applications, including soil stabilization, erosion control, retaining walls, and slope protection. They have become an important tool in civil engineering, allowing for the construction of stable and durable structures even in challenging soil conditions.

What are the different types of geocells?

There are several different types of geocells available, each with its own unique properties and characteristics. The most common types are:

- High-density polyethylene (HDPE): These are the most widely used type of geocell and are made from high-density polyethylene sheets that are welded together to form a honeycomb-like structure. HDPEs are flexible, durable, and resistant to weathering and chemical attack.

- Polypropylene (PP): PP geocells are similar to HDPE,but are made from polypropylene sheets. They are lightweight, flexible, and have good chemical resistance.

- Polyester (PET): PET geocells are made from polyester sheets and are used in applications where high-temperature stability and chemical resistance are required.

- Textile: Textile geocells are made from woven or non-woven materials and are used in applications where flexibility and permeability are important. They are often used for erosion control and slope stabilization.

- Geocells with geogrid reinforcement: Geocells can also be reinforced with geogrids, which are high-strength polymer grids that provide additional stability and strength. These reinforced geocells are used in applications where high loads or steep slopes are involved.

How does geocell work?

Geocell works by confining and stabilizing soil or aggregate within their three-dimensional honeycomb-like structure. When installed on a surface, such as a slope or embankment, the geocell is filled with soil, aggregate, or other material. The material fills the cells, creating a stable foundation or structure.

The cells of the it act as a barrier, preventing the material from shifting or sliding. The confinement of the material within the cells increases the load-bearing capacity of the soil, making it more stable and resistant to erosion.

Geocells also distribute loads more evenly over the surface of the soil, reducing stress concentrations and preventing deformation or failure. This makes them particularly effective for slope stabilization, retaining walls, and other applications where the soil is subject to heavy loads or erosion.

In addition to their stabilizing properties, geocells can also provide environmental benefits. By reducing erosion and improving soil stability, they can help prevent sediment runoff and protect water quality.

What are the benefits of using geocells?

There are several benefits to using geocells in civil engineering and soil stabilization applications. Some of the main benefits include:

- Increased stability: Geocells confine and stabilize the soil or aggregate within their honeycomb-like structure, increasing the load-bearing capacity of the soil and making it more stable. This can help prevent erosion, soil subsidence, and other types of instability.

- Improved durability: They are made from durable materials and can withstand harsh environmental conditions, such as extreme temperatures, UV radiation, and chemical exposure. This makes them a long-lasting solution for soil stabilization and erosion control.

- Cost-effective: Geocells can be a cost-effective solution compared to traditional soil stabilization methods, such as concrete or asphalt. They require less material and labor to install, resulting in lower construction costs.

- Environmentally friendly: They are made from recyclable materials and can be easily reused or recycled at the end of their useful life. They can also help prevent soil erosion and protect water quality, making them an environmentally friendly solution.

- Versatile: Geocells can be used in a wide range of applications, including slope stabilization, retaining walls, road construction, and erosion control. They can be customized to fit the specific needs of each project and can be installed on a variety of soil types.

What are the different applications of geocells?

Geocells have a wide range of applications in civil engineering and soil stabilization. Some common applications of geocell include:

- Slope stabilization: They can be used to stabilize slopes and prevent soil erosion. The cells confine the soil, preventing it from shifting or sliding, and the honeycomb-like structure distributes loads evenly over the surface of the slope.

- Retaining walls: Geocells can be used to construct retaining walls, which are structures that hold back soil or other materials. The cells provide stability and prevent the soil from shifting or sliding.

- Road construction: They can be used in road construction to reinforce the soil and provide a stable foundation for the road. They can also be used to create roadside ditches and to prevent erosion along the edges of the road.

- Landfills: Geocells can be used to construct landfill cells, which are areas where waste is deposited. The cells provide stability and prevent the waste from shifting or settling.

- Mining: They can be used in mining applications to stabilize the soil and prevent erosion. They can also be used to construct retaining walls and to create stable access roads.

- Erosion control: They can be used to prevent erosion in areas where soil is exposed to water or wind. They can be used to stabilize shorelines, riverbanks, and other areas where erosion is a problem.

Conclusion

In conclusion, geocells are a versatile and effective solution for soil stabilization and erosion control in a wide range of applications. They offer several benefits, including increased stability, improved durability, cost-effectiveness, environmental friendliness, and versatility.

Geocells have a long history of use in civil engineering and soil stabilization, and their technology continues to evolve to meet the changing needs of different industries. Overall, they are a reliable and efficient solution that can help prevent erosion, protect infrastructure, and ensure the safety and stability of various structures and environments.